Design

Industry Leaders For Design Services Dedicated to Elevating Your Product

Foster Plastics Industries offer a full spectrum of design engineering services with product design, prototyping and in-house tool making to optimise percision and efficiency. We provide customers with a complete end-to-end design experience assisting at each stage of the development cycle.

CONNECT WITH OUR EXPERTS for personalised advice and estimates to bring your vision to life.

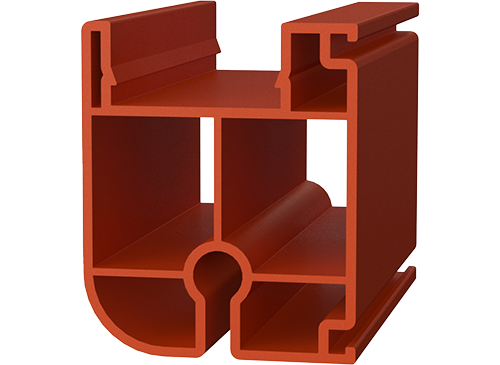

Product Design

Whether it your design or you would like us to take control we are here to help.

Our skilled team of designers, engineers, and toolmakers collaborate with you to create a tailored design solution that aligns with your budget, schedule, and quality standards. Whether you’re just starting with an idea or CAD models, we guide you in selecting the optimal design, materials and manufacturing process.

Material Selection

We assist to select the material to meet your product requirements.

We have extensive access to comprehensive material databases and can customise compounds to fulfill even the most specific and challenging requirements. Our team can advise on the optimal materials to suit your engineering needs, manufacturing processes, and budget constraints.

Rapid Prototyping

3D Printing Services

Our 3D prototyping services offers fast and convenient solutions to help you evaluate your inventions and ideas before committing to costly tooling and production.

3D Scanning Services

Our 3D scanning services are ideal for reverse engineering, verifying parts, and comparing 3D models. With cutting-edge scanning technology, we ensure highly accurate results.

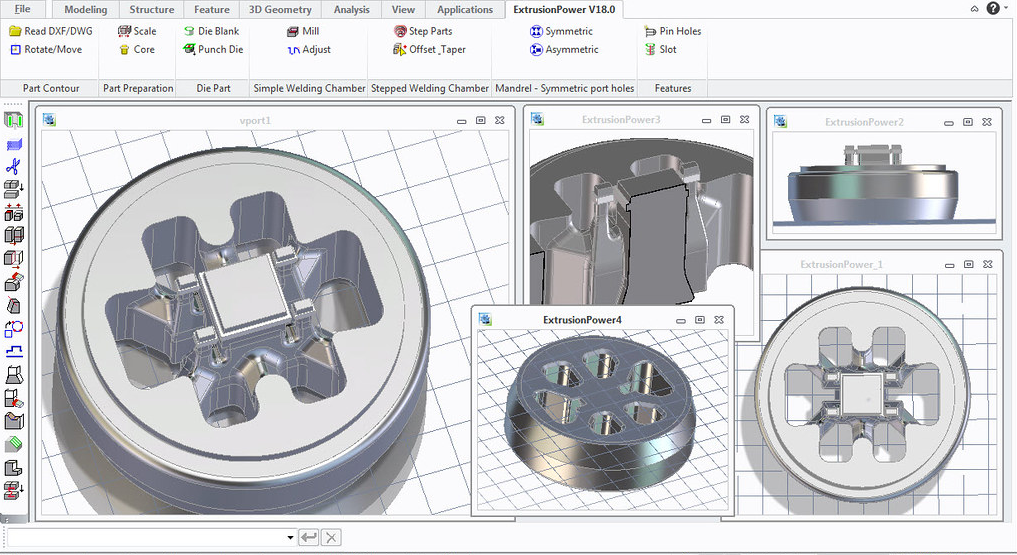

Expert Tooling Design

Our design specialists optimise the tooling design to ensure the final product achieve its specific application.

- Tools are optimised for your part and application.

- Leading CAD/CAM modeling software and precise toolmaking programs are used.

- Tolerances are aligned with the products application.

In-House Tooling Fabrication

Our specialised toolmakers craft tooling in-house to ensure our tools optimise production.

We uphold the highest standard of fabrication, proudly believing that exceptional tools are the foundation of high-quality products.

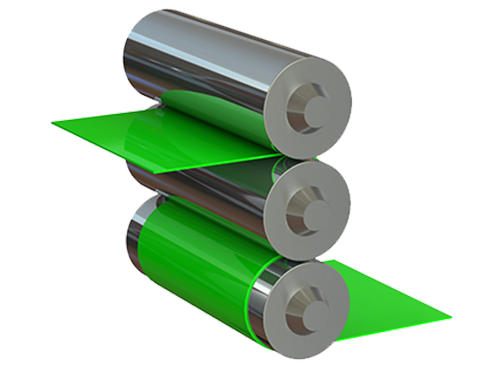

Production Trials

Extrusion tooling is trialed and fine tuned by our extrusion experts so that your design truly comes to life.

Dies are tested on our extrusion lines and off-tool samples made for customers to physically see the end product prior to the first production run.

Frequently Asked Questions

Can you help with designing custom plastic profiles?

Yes, our design team can assist you in creating custom plastic profiles. Whether you have a specific design or need help with development, we can provide expert guidance.

What is the lead time for prototyping a custom design?

Prototyping typically takes between 2 to 4 weeks, depending on the complexity of the design. We work closely with clients to ensure their design meets specifications before moving to full production.

How much does it cost to make tooling for a custom product?

Tooling contributions can vary widely depending on the complexity of the design, size of the profile, and material requirements. Extrusion tooling is generally more cost-effective than tooling for other manufacturing processes, like injection molding, making it an affordable option for custom and complex profiles. We are happy to provide a detailed quote based on your specific requirements – just reach out to discuss your project!

What file formats do you accept for custom designs?

We accept most standard file formats, including CAD files (such as .dwg and .dxf), PDFs, and sketches. If you have specific requirements, our team will guide you on how to submit your designs.

How do you ensure that the design matches my specifications?

We use advanced design software and prototyping techniques to ensure that your design is accurate. We also offer pre-production samples for your approval before mass production begins.

What materials can I choose from for my custom design?

We offer a variety of materials, including PVC, ABS, HDPE, and more. Our team can help you choose the best material based on your project’s needs and industry standards.